Understanding the Science Behind Ceramic Coating for Enhanced Vehicle Toughness

The science of ceramic covering is revolutionizing vehicle maintenance by offering a formidable guard versus harsh environmental elements. At its core, this modern technology harnesses the power of silicon dioxide and titanium dioxide to form a resilient, protective layer. However what precisely makes these substances so effective in guarding an automobile's exterior? As we discover the intricate make-up and application process of ceramic finishes, we reveal the keys behind their premium security and durability. How does this compare to typical approaches, and what ramifications does it have for car upkeep in the long-term? The responses may stun you.

Composition of Ceramic Coatings

Ceramic layers are mainly made up of silicon dioxide (SiO2), which is derived from all-natural products like quartz and sand. This compound creates the foundation of the finishing, providing its particular hardness and resistance to ecological components. In addition to SiO2, ceramic finishes often include titanium dioxide (TiO2) for improved UV defense and enhanced resistance to toxic wastes. These nanocomposite materials produce a durable, chemical bond with the lorry's surface area, providing a long-lasting safety layer.

The formula of ceramic finishes is a thorough process where the concentration of SiO2 can considerably influence the finish's efficiency. Greater SiO2 web content commonly causes greater sturdiness and firmness, adding to the finish's capacity to stand up to scrapes and chemical etching. The equilibrium of elements is important; as well much SiO2 can make the covering fragile, while too little can endanger its safety buildings.

Makers may also integrate added compounds, such as polysilazane, to enhance flexibility and convenience of application. These ingredients improve the covering's hydrophobic properties, ensuring water and impurities bead off the surface easily. This engineered make-up emphasizes the effectiveness of ceramic coatings in guarding an automobile's exterior versus a range of adverse problems.

Application Process Clarified

Applying a ceramic layer to an automobile involves numerous vital actions, each necessary to guaranteeing optimum bond and efficiency of the protective layer - ceramic coating. The procedure begins with a detailed laundry and purification of the car's surface area to remove dust, crud, and previous waxes or sealers. This step is essential as any pollutants left externally can impede the layer's ability to bond efficiently

Adhering to the first cleaning, the next step involves polishing the lorry to remove any flaws, such as swirl marks or scrapes. Polishing makes sure a smooth surface area, which is important for the layer to adhere appropriately and give an uniform surface. After brightening, a surface area prep work spray is used to remove any type of continuing to be deposits and ensure that the surface is completely tidy.

Safety Benefits

Usually hailed for its extraordinary safety qualities, a ceramic finish offers many advantages that considerably improve lorry resilience. At its core, ceramic layer forms a hard, semi-permanent barrier over an automobile's outside, which acts as a shield against different ecological threats.

Moreover, ceramic finishings show hydrophobic homes, indicating they drive away water and facilitate a self-cleaning effect. This quality minimizes the adherence of dust and mud, streamlining upkeep and cleansing procedures. The covering's resistance to chemical etching even more guarantees that the automobile's surface area stays unblemished regardless of direct exposure to rough cleansing representatives and toxins.

In enhancement to these safety advantages, the ceramic layer boosts a vehicle's visual allure by developing a shiny surface that highlights color depth discover here and clarity. This not only sustains the lorry's aesthetic allure yet likewise contributes to its long-lasting value by preserving the honesty of its outside gradually.

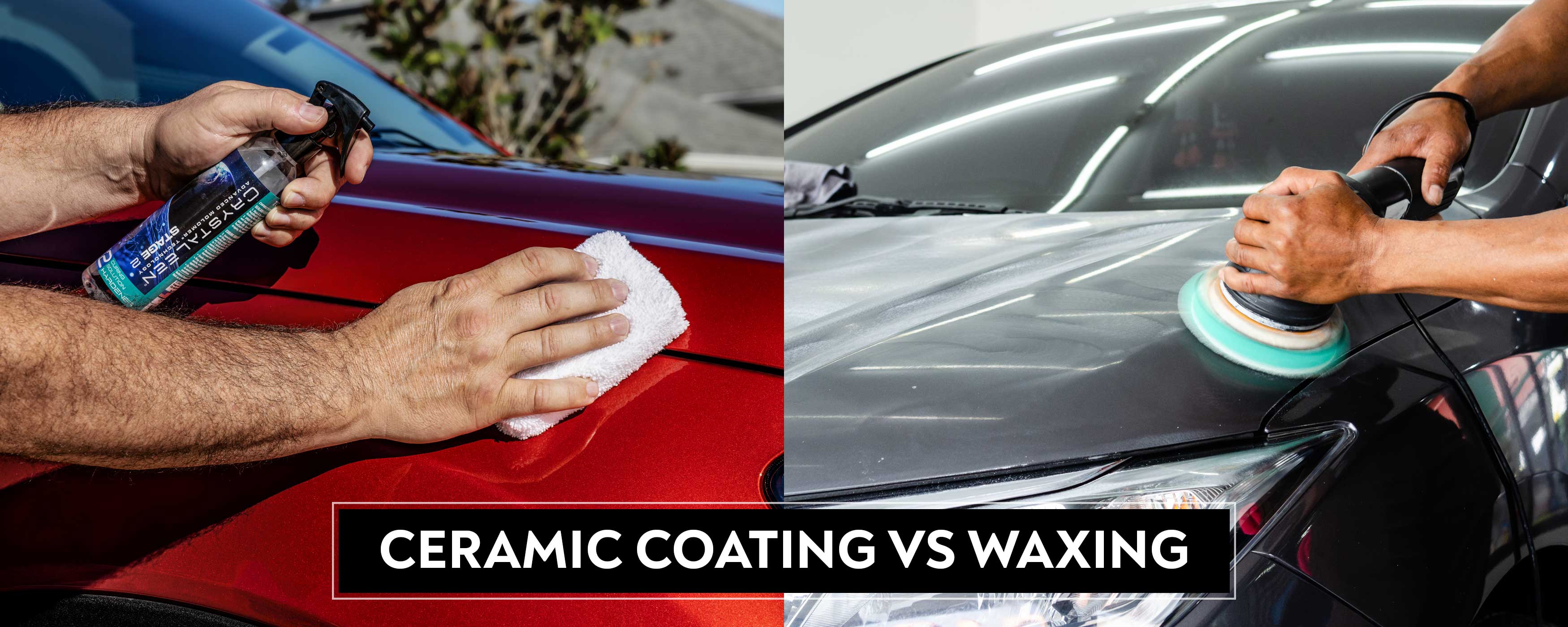

Comparing to Standard Approaches

Unlike conventional methods of automobile defense, such as shaving or sealants, ceramic coverings provide an even more long-lasting and sturdy remedy. Where waxes and sealers normally offer a short-term layer of protection, usually calling for reapplication every few months, ceramic coatings create a semi-permanent bond with the automobile's paint. This bond creates a safety layer that is immune to Full Article environmental impurities, UV damage, and small abrasions.

Standard waxes are mainly made up of natural components like carnauba wax, giving a glossy coating however doing not have the robust safety high qualities of ceramic coverings. Sealers, while synthetic and offering a little better longevity than waxes, still fall brief in comparison to the strength and chemical resistance of ceramic finishings. The advanced innovation of ceramic coatings integrates nanotechnology, which allows them to fill out tiny flaws in the paint surface area, resulting in a smoother and a lot more hydrophobic finish.

In terms of application, ceramic layers require an even more meticulous process, usually necessitating specialist installation to guarantee optimum performance. This contrasts with the fairly uncomplicated application of sealants and waxes, which can be applied in the house. However, the exceptional defense and visual enhancement supplied by ceramic layers justify the investment for those seeking lasting lorry preservation.

Longevity and Maintenance

Just how does the long life of ceramic finishes equate into convenience of upkeep for car owners? The innovative formula of ceramic coverings provides a durable protective layer on the vehicle's surface area, which substantially extends the life expectancy of the automobile's exterior coating.

In addition, the hydrophobic nature of ceramic coverings allows water and various other fluids to bead up and roll off the surface, bring dust and particles with them. While the coating itself is lasting, it is not completely maintenance-free. Hence, ceramic coatings offer a useful equilibrium in between lasting durability and streamlined upkeep for vehicle care.

Final Thought

Ceramic coatings, with their innovative chemical structure of silicon dioxide and titanium dioxide, provide an awesome barrier against environmental damages, considerably boosting automobile sturdiness. When contrasted to standard methods, ceramic layers use superior security against UV rays, oxidation, and chemical etching - ceramic coating.

The solution of ceramic coverings is a thorough process where the focus of SiO2 can significantly affect the covering's efficiency.Applying a ceramic finishing to a vehicle includes numerous crucial actions, each important to making certain optimal bond and efficiency of the protective layer.Typically hailed for its remarkable protective top qualities, a ceramic covering uses countless benefits that considerably boost vehicle sturdiness. The innovative solution of ceramic coverings supplies a durable safety layer on the vehicle's surface, which substantially expands the lifespan of the automobile's outside coating.Ceramic coatings, with their advanced chemical structure of silicon dioxide and titanium dioxide, supply an awesome obstacle versus ecological damages, significantly enhancing automobile toughness.